Life Cycle Assessments

Make the Case for Reusable Textiles

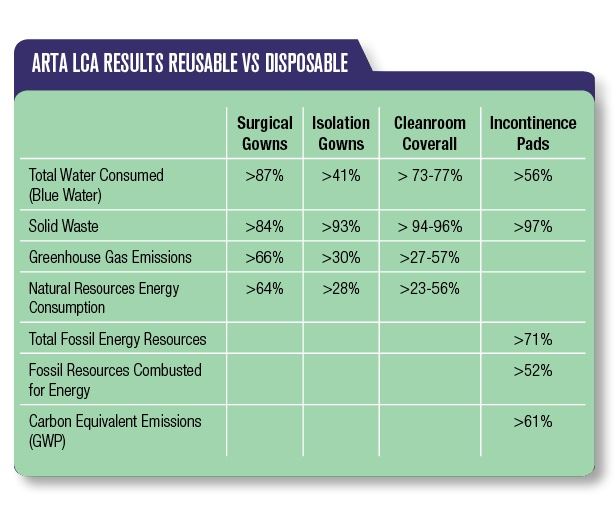

Reusable Textiles: The Responsible Choice For nearly a decade, published, peer-reviewed life cycle assessments (LCAs) have been the cornerstone of ARTA’s case for reusable healthcare textiles. Since 2013, it has conducted comparative LCAs on cleanroom coveralls, isolation gowns, surgical gowns, incontinence pads, and later this year, microfiber cleaning cloths and flat mops. The studies, conducted by Environmental Clarity researchers Michael Overcash, PhD., and Evan Griffing, PhD., compare the environmental impacts of reusable textiles versus their single-use counterparts from the origin of the raw materials, through the manufacturing process and transport, use and reuse, to the final disposal. Through its research ARTA has provided incontrovertible evidence that reusables offer dramatic improvements in environmental benefits versus their single-use counterparts, an important consideration since the healthcare industry accounts for nearly 5% of greenhouse gas emissions globally and 9% to 10% domestically. And the problem has been getting worse. U.S. healthcare greenhouse gas emissions rose 6% from 2010 to 2018, and is now the highest among industrialized nations, according to HealthAffairs. Reusable (washable) isolation gowns, surgical gowns, cleanroom coveralls and incontinence pads use less water, energy, and have much less impact on global warming than disposables. In addition, choosing reusables reduces solid waste by 84% to 97%, as well as lowering waste disposal costs, because a reusable textile is used many times while a disposable item is used once and sent to the landfill or incinerated. Medical waste is a particularly important issue because it results in carbon dioxide and other greenhouse gas emissions that stay in the earth’s atmosphere for tens to hundreds of years, warming the climate and impacting present and future generations. This foundational work is more important today than ever before since the calamitous cost of the environmental damage caused by disposables was laid bare by the COVID-19 pandemic. “Since 1982, ARTA has consistently reminded its members and the industry that ‘The Future Is Not Disposable,’” said ARTA President Gabriel Boardman. “We have invested more time, energy, and resources in recent years to provide the industry with an increased number of studies to strengthen our message and illustrate clearly the positive impact of reusables for the healthcare industry.”. |

ARTA’s life cycle assessments prove that reusable (washable) textiles use less water and energy and have much less impact on global warming than disposables. In addition, choosing reusables reduces solid waste by 84% to 97% and lowers waste disposal costs.

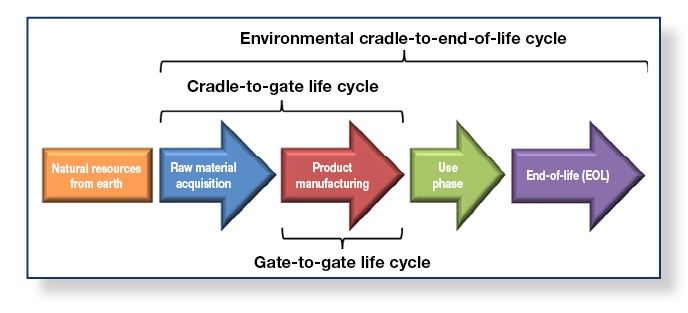

Environmental Clarity uses this LCA process and data from the Environmental Genome database to compare the environmental impacts – energy and water consumption, global warming potential (carbon footprint), and solid waste creation – for reusable and disposable textiles. environmentalgenome.org |

Why Life Cycle Assessment? Life cycle assessment is the most comprehensive and widely used tool used to evaluate environmental impacts of products, services, or processes from cradle-to-grave. First developed in the United States and then in Europe in the late 1960s and early 1970s, the studies were pioneered by private industry and later used, promoted, and even mandated for some applications by government agencies. Coca-Cola Co. pioneered the LCA in 1969 to compare the environmental impact of its beverage containers and helped to lay the foundation for its use in the U.S. The company conducted the study at a time when addressing water and air pollution was a priority for newly elected President Richard Nixon who launched the Environmental Protection Agency (EPA) in 1970. The EPA, then looking for a way to reduce waste streams and strengthen recycling efforts, refined the methodology. A systemized framework for conducting LCAs was released by the International Organization for Standardization between 1997-2000, and previous standards were combined into ISO 14040 and 14044 in 2006 that are still the standards used for LCAs today. The European Platform on Life Cycle Assessment was established in 2005 to promote the availability, exchange, and use of quality-assured life cycle data, methods, and studies for reliable decision support in EU public policy and business. LCAs have gained ground throughout this decade and today governments in many parts of the world encourage the utilization of LCAs as a core element in environmental policy.

ARTA’s Microfiber LCA The next research project is an LCA the ARTA Microfiber Committee is conducting to compare reusable and disposable products for two common environmental services products – the microfiber cleaning cloth and the flat mop. The studies of both the reusable and the disposable cleaning products, to be completed in 2022, include the following components:

This project will be set up with a clear study hypothesis and conclusions, linked to the life cycle literature to assure tha a quality, peer-reviewed paper can be published. The primary intended audience is nurses, physicians, healthcare purchasing personnel, and healthcare administrators. By Dory Trinka. Trinka is a freelance writer and editor and provides content management services to businesses and nonprofits. dtrinka@nextpathpartners.com | The Evolution of ARTA Research: Economic Impact Studies ARTA understands that product purchase decisions are multifactorial and that understanding the true economic costs of the available alternatives is critical. So, it has undertaken a series of Economic Impact Studies for reusable and disposable cleanroom coveralls, isolation gowns, surgical gowns, incontinence pads, and microfiber cleaning products. Environmental Clarity published the first of these Economic Impact Studies on cleanroom coveralls in 2021, based on a compilation of 22 cleanroom customer documents from laundry operators and suppliers representing all four regions of the U.S. and with a wide range of annual usage. Published in the peer-reviewed PDA Journal of Pharmaceutical Science and Technology, the study was the first such report on cleanroom garments, which are used by many industries, including the semiconductor, pharmaceutical, life science research, medical device manufacturing, and food manufacturing. Conducted for ARTA’s Cleanroom Committee, the study estimated that about 50% of garments purchased for U.S. cleanrooms are reusables and 50% are single-use garments. The results are based on an industry-wide distribution survey that also found that 40% of the reusable garments must be laundered and sterilized and yield about 40 uses. The remaining 60% only require laundering and are used 80 times. The Economic Impact Study on cleanroom products documents that the cost of use for reusables is 58% less expensive than their disposable counterparts, which saves $120 million in annual garment purchases and laundry costs annually. Reusable cleanroom coveralls also save 136 million megajoules (MJ) of natural resource energy and global warming potential, the equivalent of removing 1,600 automobiles from the roads annually. The solid waste disposal savings for selecting reusables was $340,000 per year. The study posed an intriguing hypothetical: If all U.S. cleanroom facilities converted to reusables (other than 12.5% of the market composed of hazmat suits, which must be disposable), the savings to the cleanroom industry and the environment, over a decade, would be: • $2.1 billion in garment purchase and laundry costs “The opportunity for the healthcare industry to simultaneously reduce environmental impact and save money on a recurring yearly basis should be more widely recognized, said Overcash of Environmental Clarity and the executive director and a board member of the Environmental Genome Initiative. “This information would be valuable in firms’ sustainability goals and economic bottom line, all by the simple decision to go with reusables.” |

.png)